- Home

- VFD Solutions

- Equipment Modification Solution

- Variable Frequency Drive in Industrial Dyeing and Finishing Dewatering Equipment

Process Requirements

A dehydration system consists of an inverter control cabinet, dehydration bucket, motor, drain pipe etc. A motor is connected to the bottom of the dehydration bucket to drive the bucket rotation in the dehydration process. A dehydration machine makes dehydrated articles generate centrifugal force, and water will be thrown off through holes in the dehydration machine, and then discharged by the drain pipe.

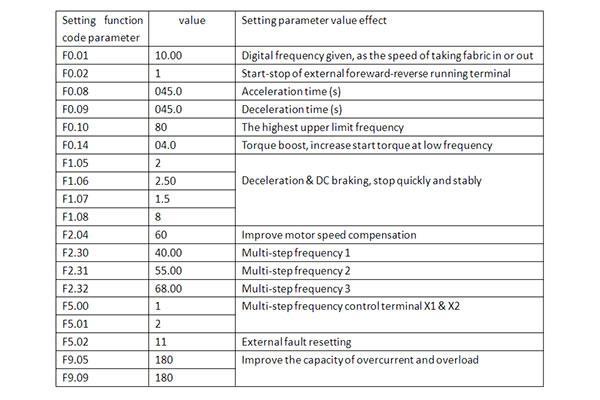

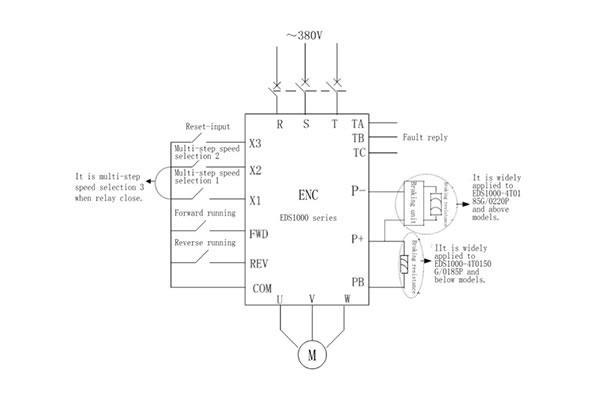

This article mainly introduces the ENC EDS1000 series inverter used in dyeing and finishing industry dehydrator application solutions. Pig.1 & Pig.2 record its work state.

EDS1000 Series Inverter Application

1. A dyeing and finishing dehydrator is a typical low damping large inertia load machine, over-current should be overcome in acceleration and over-voltage in deceleration.

2. It requires large torque at low frequency and start forcefully to avoid frequency over-current and over-voltage errors. Owing to the large instantaneous current and voltage, super over-load and over-voltage ability is required for smooth and steady stopping.

3. During high-speed dehydration, the motor shouldn't lose its speed to cause over-voltage errors, which may reduce production efficiency.

4. It can work for a long time in wet and pollution controlled environments.

For more details, please download the following document:

Dyeing and finishing industry dehydrator application solution PDF